Don’t Ignore these 4 Signs of an Electric Motor Problem

Electric motors are essential components in a wide range of applications, from industrial machinery to household appliances. When operating correctly, they provide reliable and efficient power. However, as they age, electric motors can develop issues, which may worsen if ignored. At Industrial Motors & Machining Inc., we provide expert electric motor repair in the greater Denver area. Here are four common signs of electric motor trouble.

Unusual Noises During Operation

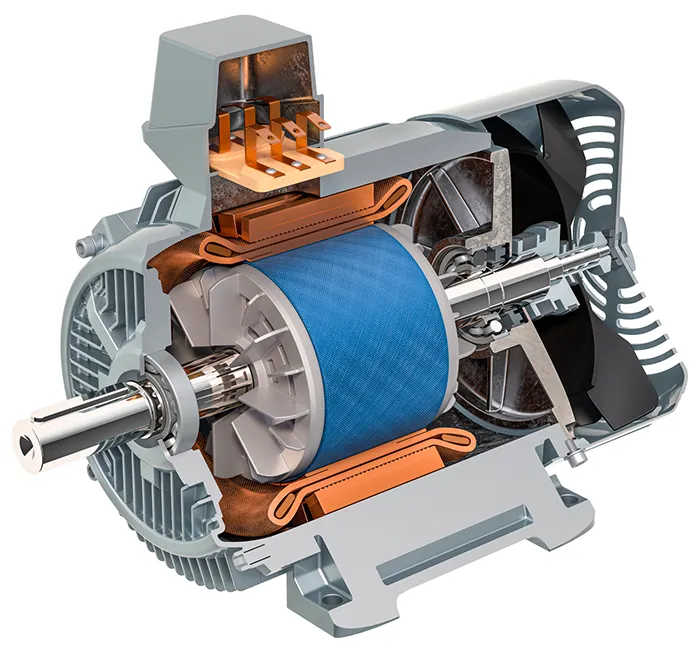

A properly functioning motor should run smoothly and quietly. If you start hearing grinding, buzzing, or whining sounds, it could be a sign of worn-out bearings, loose components, or misalignment. Ignoring these sounds can lead to further damage, so it’s important to address the issue promptly by inspecting and servicing the motor.

Overheating

Excessive heat is another clear sign of trouble with an electric motor. While motors naturally generate some heat, overheating beyond normal levels can indicate underlying issues such as inadequate ventilation or overloading. Prolonged overheating can damage the motor’s internal components and reduce its lifespan. Regularly monitoring the motor’s temperature and addressing any overheating issues can prevent significant damage.

Reduced Performance or Power Output

If your electric motor is no longer delivering the same level of power or performance, it may be struggling with internal problems. A drop in speed, torque, or overall efficiency could be caused by worn brushes or damaged windings. In some cases, reduced performance may also result from external factors like voltage fluctuations or improper load distribution. Conducting a thorough inspection can help pinpoint the cause and restore the motor’s performance.

Excessive Vibration

Excessive vibration during motor operation is another warning sign that something may be wrong. Common causes of vibration include misaligned shafts or worn-out bearings. Over time, unchecked vibration can lead to additional wear and tear on the motor and connected equipment. Regular maintenance and alignment checks can help reduce vibration and prevent further damage to the motor and its components.

Electric Motor Repair in Denver, CO

If you need

electric motor repair in Denver

or the surrounding area, contact Industrial Motors & Machining Inc. at

303-872-5981. Come and see us for your electric motor needs!