Industrial Motors & Machining

PROUDLY SERVING DENVER & SURROUNDING AREAS

Electric Motor Repair, Electric Motor Sales, Welding & Machining in Denver and the Surrounding Areas

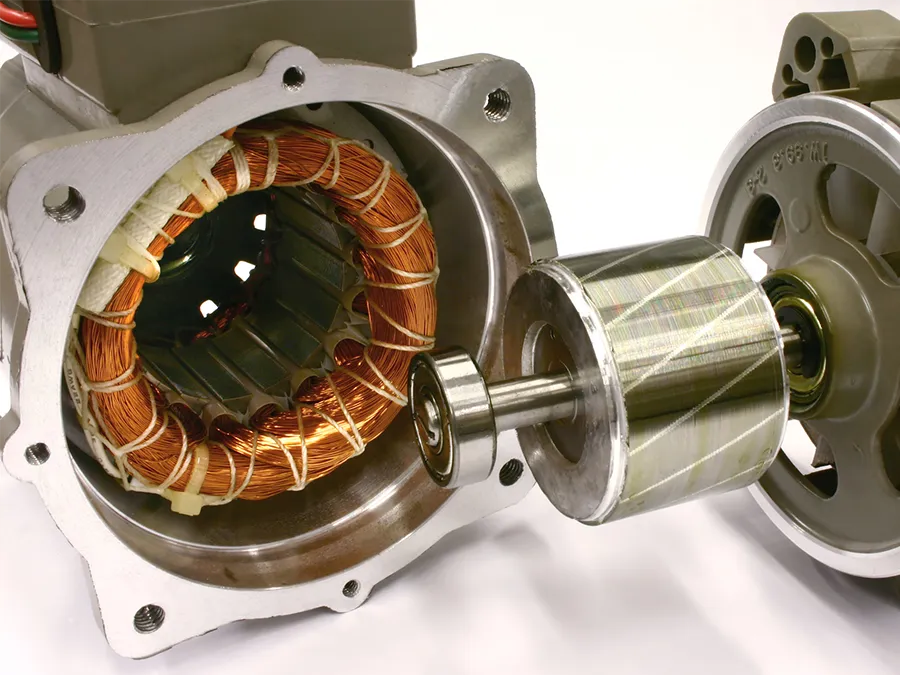

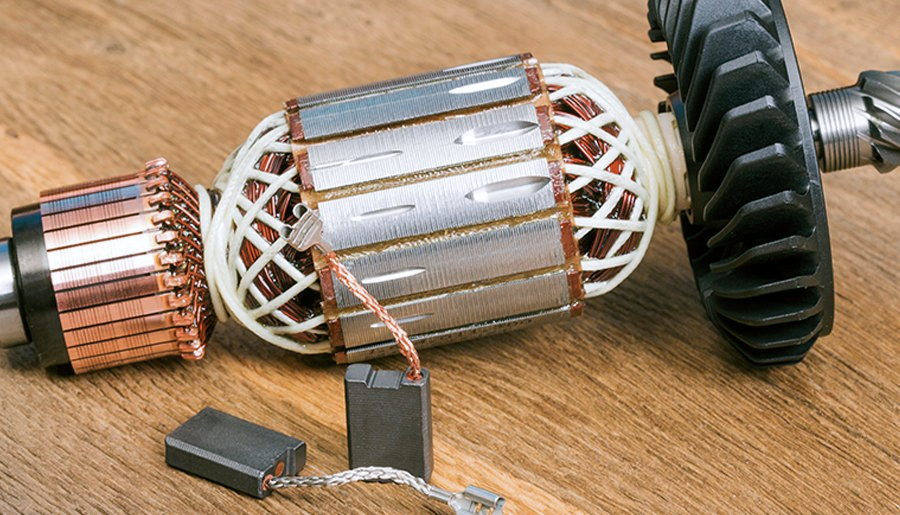

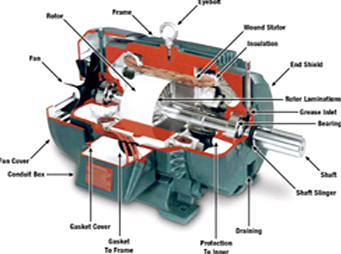

Electric Motor Repair

Expert repair and rebuilding for all types of electric motors and accessories.

Electric Motor Sales

We have a huge lineup of electric motors for sale for all kinds of equipment.

Welding & Machining

Our full service facility provides a wide variety of machining & welding services.

Our Services

- AC Electric Motor Sales

- DC Electric Motor Sales

- Electric Motor Repair

- Electric Motor Rebuilding

- Motor Rewinding

- Motor Redesign

- Motor Troubleshooting

- Expert Welding & Machining

- Hoist Repair & Pump Repair

- Metric Motors

- Rebuilt Elevator Motors

- New AC/DC Drives

Industrial Motors & Machining is a Denver electric motor shop specializing in top-quality, cost-competitive electric motor sales, service and repair, as well as welding and machining.

We offer electric motors for sale from every manufacturer, and can advise you on the best motors for your needs. We're an authorized service center for most manufacturers, and we also offer machining services and troubleshooting, ensuring fast turnarounds for electric motor repairs and rebuilding. To learn more about our local electric motor shop, call us and a friendly crew member will be happy to answer any questions or provide you with a quote.

Quality is everything at our nearby electric motor repair shop. Our work meets the absolute highest standards, as exemplified by our membership in numerous professional organizations. We're members of Underwriters Laboratories (UL), Electrical Apparatus Service, and the US and Denver Chambers of Commerce. We are proud to have been serving business and individuals in Denver, Aurora, Broomfield, Westminster and beyond for almost 50 years, and we continue to meet and exceed the high expectations of our clients. When it’s time for a rebuilt or new electric motor, our sales team has access to motors from any manufacturer and can provide you with the expert advice you need to make a smart decision for your home or business. As an authorized repair facility for most electric motor manufacturers, we can expertly perform any motor repair service you may require, including AC and DC motor repair, fractional horsepower (FHP) motor repair, rewinding and redesign, welding and fabrication, troubleshooting, alignment, balancing and more. We encourage you to give Industrial Motors & Machining a call at

(303) 872-5981 so we can show you why our friendly, honest, fast and fair-priced services have made us the go-to electric motor experts in Denver for nearly five decades.

Industrial Motors & Machining Blog